In addition to providing design services for healthcare projects, TAHPI is experienced in the Design and Construction of prefabricated and/or modular Hospital buildings. TAHPIs expertise covers all aspects of prefabrication both Soft and Hard Modular.

Modular

Soft Modular

TAHPI is experienced in the componentisation of design, for both Prefab and Modular Health Facility Projects. We create a catalogue of design elements that fit into the building grid easily and are capable of replication throughout the project without variation. TAHPI has been preparing standard components of design at the Room level as well as the Room content level since the year 2000. These components are already built into numerous Health Facility Standards and Guidelines created by TAHPI and used by multiple government health authorities around the world. The information and specifications for these soft modular components built by TAHPI translate directly into these health facility standards and guidelines such as the International Health Facility Guidelines (iHFG), the Indian Health Facility Guidelines, Abu Dhabi Health Facility Guidelines and many more.

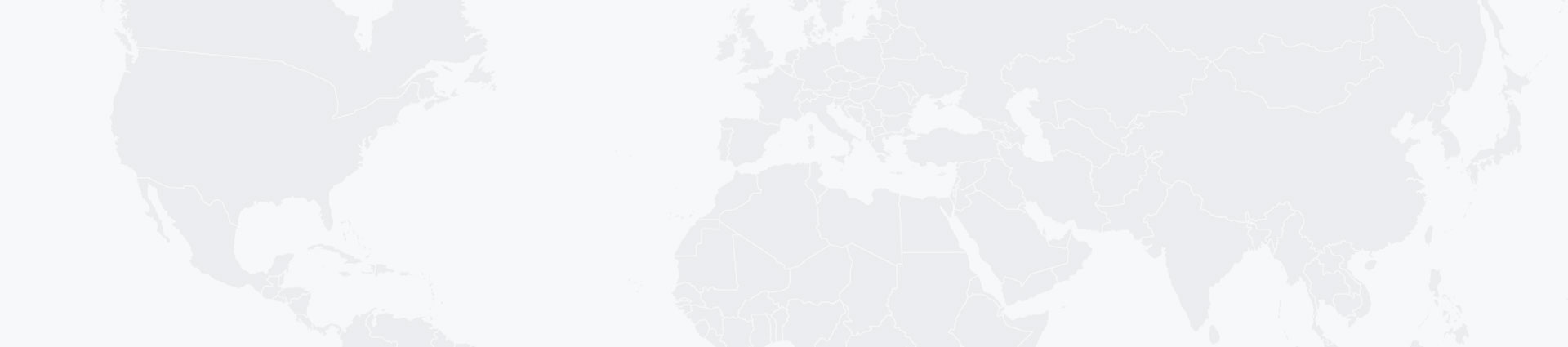

Even the most complex hospitals using varied shapes and forms can be componentised:

University of Malaya Health Metropolis demonstrating Soft Modular approach

Hard Modular

TAHPI, in collaboration with a Prefab and Modular factory has established an International Design Studio to advance the design and production of high quality but affordable modules for future hospitals.

This is the actual fabrication and assembly of the modular design components. There are many methods developed over time to suit a variety of circumstances:

Component Assemblies– This involves the construction all the walls off-site. These are generally in steel frame with one or both sides sheeted. All built-in elements including external windows and glazing are completed off-site, then assembled over a concrete slab or light flooring once delivered to the site as flat packs. Roof elements are prepared and delivered to the site in the same manner. HPI was responsible for the design of the Lady Davidson Hospital using this methodology. The project, one of the lowest costs per unit included 90 beds fully completed in less than 6 months including commissioning.

Whole-room Modules

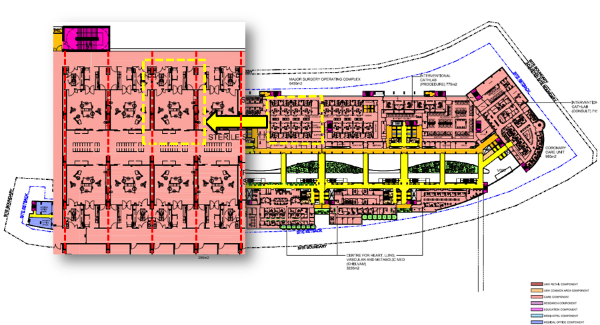

This technique involves the off-site prefabrication of whole rooms plus the corridor in between. These are based on the shipping container structural system or proprietary steel construction.

Once delivered to the site, these can be assembled easily as they have their own floors, walls, ceilings and structural system. Internally they are fully completed. They can be stacked several storeys high. They can have concrete or FC flooring.

TAHPIs Australian arm HPI was responsible for the design of the Lake Macquarie Private Hospital using this system.

Whole room units are factory assembly and quality controlled

Prefabricated Structure and Facade

This takes the conventional prefabrication of external walls to its ultimate potential.

In addition to the facades, the columns, beams and floor planks are prefabricated off-site and assembled rapidly onsite. The floors are designed to enable the use of whole room modules internally. This type of construction suits multi-storey buildings in a concrete frame.

TAHPI is responsible for the PHS hospital utilising this technique.

KEF-TAHPI and Modular Showroom

In 2013, TAHPI and KEF joined forces to create KEF-TAHPI, based at Dubai Healthcare City. KEF TAHPI is dedicated the turnkey design and construction of Prefabricated hospitals (including the PHS hospital shown above). KEF-TAHPI facilities include a Design Studio at Dubai Healthcare City, Factory No 1 outside Bangalore, India and Factory 2 at Jabal Ali, in Dubai. The factories incorporate all elements of prefabrication including:

- Concrete Columns, Pre-tensioned beams, Floor Planks

- Prefabricated Concrete Facades

- Aluminium windows and façade panels

- Doors and Door Frames

- Steel wall frames and sheeting

- Room Pods (individual pods up to 7m2 and flat packs above 7m2)

- Joinery and woodwork

- Fire Stairs

- Modular MEP

The KEF-TAHPI Modular showroom was first launched at Arab Health 2015 expo in Dubai. The showroom included 4 realistic modules for demonstration including a Patient Bedroom, Bathroom, Dirty Utility Room and Reception.